Research Interests

Process and energy systems consist of a broad category of processes and systems but are vital to most if not all, major sectors. Given the increasing need to be more responsible humans, global pressure continues to mount to increase clean energy source utilization, incorporate more renewable energy sources, and provide electricity demand flexibility to improve the overall grid efficiency and reliability. Buildings make up a large portion of electricity consumption, with HVAC responsible for a significant fraction of the overall consumption of buildings. Numerous research and proof-of-concept works have demonstrated the potential of advanced control and optimization technologies to save significant operating costs. Additionally, the chemical process industry remains vital to the US and global economies. Thus, optimizing the performance of chemical processes is crucial for maximizing production while minimizing operating costs and energy consumption.

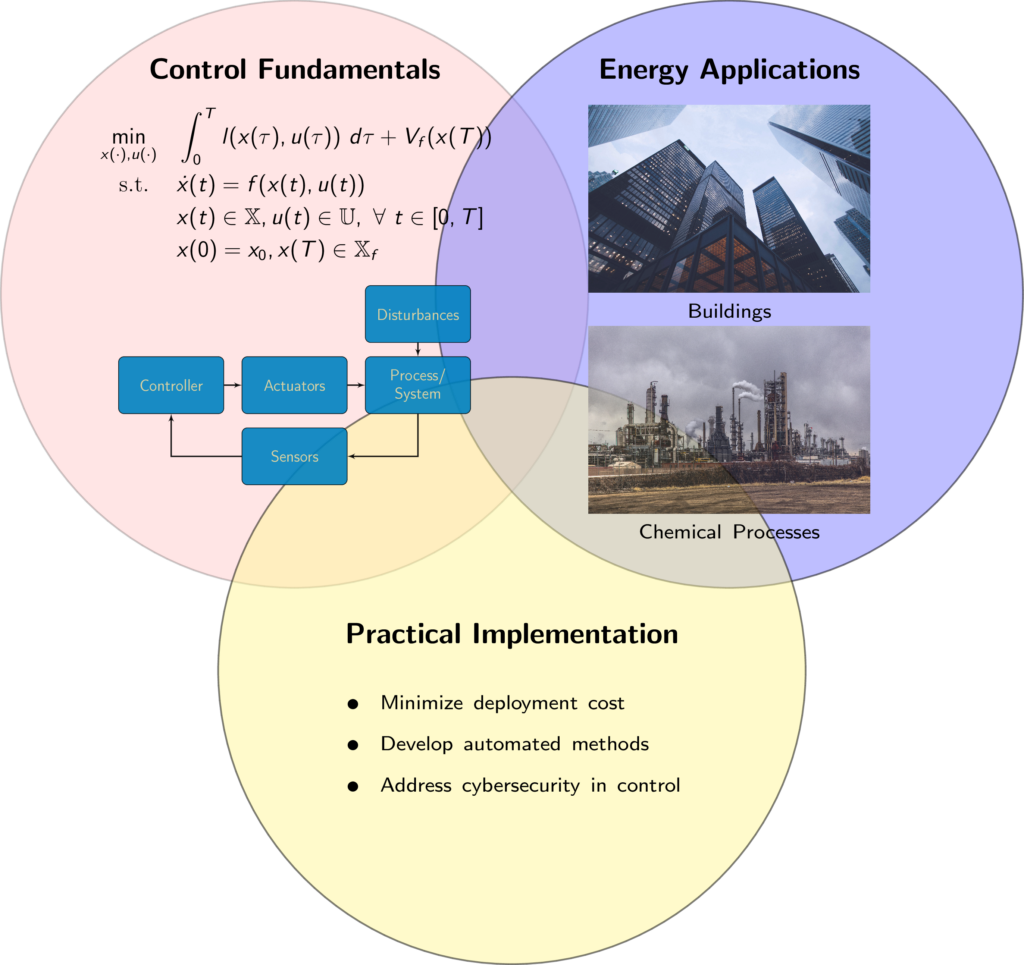

The Ellis laboratory of Control and Optimization of Energy Systems works at the center of control fundamentals, practical implementation, and energy system applications to address key challenges faced within the control and optimization of energy systems. Our mission is to:

- Expand the theoretical foundation of control and optimization of process and energy systems

- Develop practical computational methods for control and optimization of process and energy systems

- Mitigate technical risk and engage in technology transfer of developed methods to empower industry adoption

To achieve this mission, we:

- Provide robust training in process systems engineer by providing our lab members a comprehensive educational experience including advanced control, optimization, model identification, estimation, process monitoring, machine learning, and professional development

- Promote an inclusive environment

- Seek out collaborations to multiply the impact of our work and address the inherently multidisciplinary nature of today’s complex problems

Our current research projects are:

- Load flexibility controls for heat pumps

- Active Control-Enabled Approaches for Handling Cyberattacks on Process Control Systems

- Machine-learning enhanced modeling for economically-oriented predictive control

Current Projects

Load flexibility controls for heat pumps

With the abundance of renewable energy sources (e.g., solar) and the increasing focus and regulations on shifting to renewable energy sources, electrification has become a dominant trend in California. In multi-family residential homes, one such example of electrification is the increasing utilization of heat pumps for hot water heating and/or space conditioning. However, the availability of renewable energy sources may be variable over the course of a day (i.e., solar power is available at varying levels during the day and unavailable at night). Advanced controls are needed for heat pumps to take full advantage of renewable energy sources and to provide load flexibility to the grid, preventing grid operations from turning on less efficient energy generation equipment during peak periods.

EMPC has been demonstrated as a good choice for control strategy for energy systems because of its unique ability to control energy systems that are subject to time-varying electric rates (e.g., time-of-use rates) while leveraging available system energy storage. For heat pump applications, energy storage is available through the building mass in space conditioning and through a hot water tank for hot water heating. Most residential heat pumps feature staged operations, meaning that the compressor and fans of the heat pump are not variable speed (may only be turned on or off), which leads to discrete or integer decision variables in the EMPC optimal control problem. In general, optimization problems with integer decisions are more difficult to solve than optimization problems with continuous decisions only. Thus, formulating the EMPC in a computationally tractable manner is critical for real-time application.

In this project, we are developing an open-source turn-key EMPC system that will be easy to use and will eliminate the need for installers or end-users to have subject matter expertise in EMPC or heat pump systems. This project will develop, test, and demonstrate an advanced control system that saves energy, improves grid reliability, and reduces greenhouse gas emissions by optimizing heat pump operation based on building owner/occupant preferences, comfort and use patterns, electricity pricing, electricity grid needs, real-time greenhouse gas emission rates, and weather data. As part of the project, the developed framework for heat pump load flexibility controls for water heating and spacing conditioning will be deployed to 25-30 low-income residential units to demonstrate the approach. This project is being completed in collaboration with the Western Cooling Efficient Center at UC Davis.

Active Control-Enabled Approaches for Handling Cyberattacks on Process Control Systems

Modern industrial control systems (ICSs) form the backbone of many critical infrastructure sectors, including chemical manufacturing, energy production, and HVAC systems. These systems integrate physical processes with cyber components through networked communications to ensure operational efficiency and safety. However, the increasing reliance on networked communications has rendered ICSs vulnerable to cyberattacks. Such attacks can result in severe physical consequences, including compromised product quality, heightened operational costs, or even risks to human safety. While traditional information technology (IT) security measures exist, recent cyberattacks on ICSs have shown that attackers can breach IT defenses, underscoring the need for operational technology (OT)-based solutions to enhance cyberattack resilience.Cyberattack resilience in ICSs refers to the ability to withstand, adapt to, and recover from cyberattacks while maintaining stability and performance. In this project, we are developing a comprehensive framework that incorporates cyberattack resilience into the design, operation, and monitoring of ICSs. This includes creating robust tools to help design ICSs with cyberattack resilience considerations, as well as development of advanced monitoring tools for detecting attacks, identifying compromised components, and estimating the severity of incidents. Additionally, accommodation strategies will be formulated to ensure safe and reliable operations during such incidents. These tools will be designed to integrate seamlessly with existing ICS configurations, ensuring practical applicability and scalability.

Machine-learning enhanced modeling for economically-oriented predictive control

Advancements in monitoring and control technologies for building energy management are anticipated to save 1.7 quads in 2030 and 3.6 quads in 2050. Additionally, demand flexibility in buildings can be leveraged to deliver grid services (e.g., load shifting, load shedding, and modulation services) and to enable increased penetration of renewable energy resources. Model predictive control (MPC) has received substantial attention from the research community for its potential to contribute to both energy savings and grid reliability. However, the extensive time and effort to build, configure, and train predictive models used within MPC for building systems are widely recognized as key technological barriers that can consume up to 70-75 percent of implementation costs preventing large-scale adoption of MPC in real buildings. As a result, easy to deploy rule-based strategies are typically employed in practice, despite their often sub-optimal performance and lack of energy savings capability.

One common MPC approach is to leverage thermal resistance-capacitance (RC) gray-box models. However, since the design and operation of every building are unique, a new RC network model may need to be developed for each building application, resulting in large deployment costs. Model-free approaches (i.e., approaches that do not require a model a priori) are also available that alleviate the costs of RC model creation; however, they are not without their challenges. Some model-free approaches, such as reinforcement learning, which leverage deep learning methods are currently in an early research stage, require large amounts of training data, and are prone to violate occupant comfort requirements. Others, such as extremum seeking controls, are more mature but have not been widely adopted due to their slow convergence to the optimal operating point and their need for continuous perturbations to identify optimal solutions.

In this project, we are developing a solution that leverages the strengths of model-based optimal control and deep learning methods while mitigating their shortcomings by enhancing gray-box modeling with machine learning modeling. This strategy will dramatically lower the costs of model construction and configuration relative to RC-based approaches, since the model will be automatically generated from a list of inputs and outputs. Additionally, the rich theoretical foundation of standard model-based optimal control approaches will be leveraged, for example, to provide closed-loop guarantees such as stability.

Previous Projects

Development and execution of test methods for demand control ventilation

Demand control ventilation (DCV) is a vital part of building ventilation, as it adjusts the outdoor air ventilation rate based directly or indirectly (i.e., through measurements of the indoor CO2 concentration) on the number of occupants. Because ventilation brings outdoor air in, which has to be conditioned, there is a trade-off between indoor air quality and energy consumption. The performance of DCV (i.e., ability to respond in the presence of variable building occupancy) has only been magnified within the last year with the global COVID-19 pandemic. This project focuses on the development of a precise and repeatable standard test methodology to quantify the performance of industrial CO2 sensors and DCV, which are used in buildings to measure CO2.